RECOMBINANT PROTEIN EXPRESSION

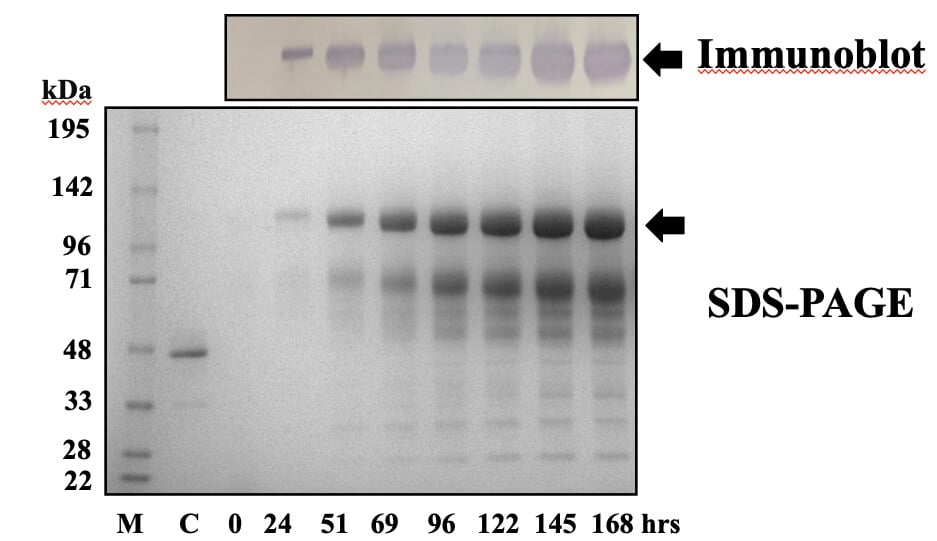

Protein production using recombinant technologies continues to revolutionize all aspects of life and life sciences. Essentially, a gene encoding a protein of interest is expressed to make the protein at dramatically enhanced yield and or with greatly improved characteristics in the native organism or in heterologous hosts. Recombinant production of proteins involves transforming cells with a desired gene in a DNA vector. The gene then translates into its corresponding protein. The expressed protein can then be extracted by lysing the cells and subsequent purification steps. In some cases, the protein made in the cells is exported into the culture medium through protein secretion machineries.

Bacterial, yeast, insect and mammalian expression systems are widely used. Each system has its own advantages and disadvantages. Selection of a particular expression system for a given protein should be based on many factors, such as the type, origin and function of the protein, technical challenges, applications, and regulatory considerations. Bio-Technical Resources offers several microbial expression systems, typically much more productive and affordable than insect and mammalian systems.

MULTIPLE MICROBIAL PLATFORM HOSTS FOR PROTEIN EXPRESSION

A brief introduction to these expression systems is provided in a downloadable PowerPoint presentation BTR multiple host systems for protein expression (pdf). In addition to these platform organisms, BTR has experience working with numerous other microorganisms such as Lactobacillus lactis, Bacillus licheniformis, Hansenula polymorpha, and Myceliophthora thermophile C1 (previously known as Chrysosporium lucknowense C1).

BTR was previously a North American representative for two proprietary protein expression systems, Hansenula polymorpha (property of ARTES Biotechnology GmbH) and Bacillus licheniformis (property of Koninklijke DSM N.V ), but no longer represents these proprietary systems. BTR will work with our clients’ specific microbial strains producing products that are categorized as BSL1.

No single host system is the best option for all types of proteins and applications. BTR has the capacity and proven experience to help you to choose and develop the most efficient production system for your protein of interest (POI).

Five non-proprietary protein expression systems are available at BTR. Please visit the respective webpages linked to the individual buttons below:

- E. coli: intracellular and secreted (periplasmic) protein

- Bacillus subtilis: intracellular, and secreted protein in particular

- Saccharomyces cerevisiae: mainly intracellular protein

- Pichia pastoris: intracellular, and secreted protein in particular

- Trichoderma reesei: secreted protein

BRT'S STRATEGY FOR SELECTING AND DEVELOPING A PROTEIN EXPRESSION PLATFORM

The microbial expression hosts offered by BTR have the potential to produce your intracellular or secreted protein of interest. Each system has strengths and weaknesses.

BTR will help you select one microbial host, via a phased Development Program, to serve as a protein expression platform to meet your present and future needs:

- Phase 1: focus on a feasibility study, using one or more host systems. This study will evaluate generated strains in shake flask culture.

- Phase 2: construct and evaluate advanced strains to improve protein expression. The "best" of the candidate production strains will be selected from shake flask and 1-L fermentor cultures.

- Phase 3: optimize a fermentation process, and scale-up and demonstrate the process at BTR's 14-L and 60-L or 250-L pilot scales. A Technology Transfer Package will be prepared that supports transfer of the strain to a commercial fermentation facility.

Several projects of R&D services in this area are highlighted in PowerPoint slideshow Protein expression examples (pdf).

FAQ

We offer five different expression systems, including two bacterial hosts (Escherichia coli and Bacillus subtilis), two yeast hosts, (Saccharomyces cerevisiae and Pichia pastoris) and a filamentous fungus (Trichoderma reesei). Target protein are expressed as intracellular proteins or secreted into the culture medium. We also work with other systems of Clients’ choice.

E. coli system is by far the most cost-effective and consistent production method. We have performed numerous Services Programs to develop E. coli strains and processes, and scale up production from milligrams to grams of protein. If not already tested for a given protein, E. coli should always be the first system to evaluate. Many proteins produced in E. coli do show activity of the native protein although E. coli do not incorporate post-translational modifications into the recombinant protein. Protein produced in E. coli may not be suitable for some applications du to endotoxin and regulatory reasons.

The main factors to consider are the native host of your protein, what you know about your protein, and intended applications. Typically, proteins of bacterial origin have a good chance to be expressed as functional protein in E. coli and B. subtilis. Proteins from eukaryotes may or may not be expressed as functional protein in E. coli. Yeast and filamentous fungus might be more appropriate. Production of protein in a secreted form is desirable for lower cost of downstream processing (product recovery).

T. ressei is a mesophilic filamentous fungus that synthesizes and secretes cellulase. Its hypersecreting mutant RUT-C30 has become one of the most widely used strains of filamentous fungi for the production of cellulase and recombinant protein. Cellulase production reached over 100 g per liter in high cell density fermentation at commercial scale. T. reesei grows in simple and cheap medium. Efficient secretion of target protein into the medium provides an opportunity for low-cost downstream processing.

Just leave a message and your contact in the contact form on our web site. BTR’s Business Development team will get in touch with you to schedule a brief technical call. If there is a good alignment between your need and BTR’s capability, an NDA will be signed to protect your confidential information before more in-depth technical discussions. A Services Program proposal will be prepared and discussed with you.

No. The only exception is when the client desires to have a Services Program done at BTR using a third-party system or materials that require licensing. In that case,the client will be responsible for licensing from the third party

BTR operates fermentors of four different sizes: 1-, 14-, 60- and 250-Liters. Process development and optimization utilize primarily 1-L fermentors (operated in sets of up to 8 fermentors). Scale-up are tested at the 14-L scale. Final scale-up and production are in either 60- or 250-L fermentors.

No. BTR is a R&D facility. However, BTR has developed numerous production processes that have been transferred and scaled up for commercial production at GMP facilities.

Bio-Technical Resources provides R&D services for a Fee. All technologies developed during a Service Program entirely belong to the Client. BTR will also assist client in preparations for patent application if requested.

The intellectual property and/or trade secrets of new and existing technologies are invaluable to the success of our clients. BTR adheres stringently to Non-Disclosure Agreements that BTR enters with its clients.

Yes. Please visit our web page of Resources – Technical, where you will find several R&D Project examples and showcases. Note that the vast majority of R&D programs performed by BTR have been confidential/proprietary efforts for clients; most of these cannot be shared with any third parties. The examples on the website are either BTR’s internal R&D programs or clients’ programs for which BTR has been given permission to publicize or only non-confidential general information is disclosed.